flexible - innovative - inspiring

Contract manufacturing / CNC laser cutting

Hohl machine and plant construction

Precision and flexibility for modern sheet metal processing

Laser cutting is used where complex contours require precise, fast processing and virtually force-free machining. Laser cutting is opening up more and more applications in sheet metal processing and stands for unique quality. Compared to alternative processes such as punching, laser cutting can already be used economically for very small batch sizes. The high level of production flexibility, combined with an almost unlimited variety of materials and shapes, is the reason for its worldwide recognition as an indispensable basic technology. The kerfs are low-burr or even burr-free and therefore rarely need to be reworked.

Key data

Sheet formats:

– up to 3,000 x 1,500 mm

Sheet thicknesses:

– Steel up to 20mm

– Stainless steel up to 10mm

– Aluminum up to 6mm

Services

- CNC laser cutting

- CNC bending work

- CNC turning and milling work

- MIG / MAG / TIG welding process

- Surface coating

- Component assembly

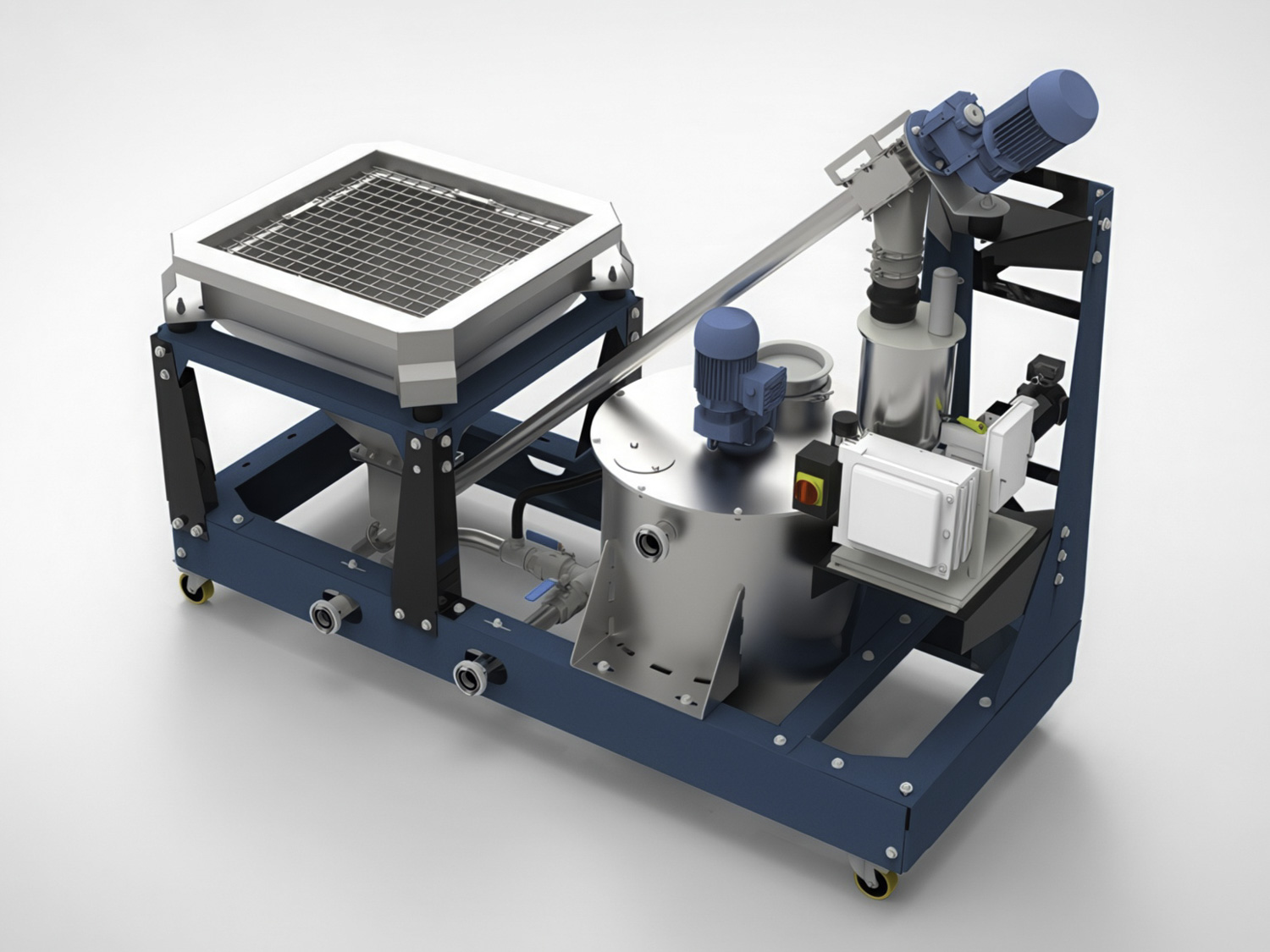

Customer-oriented system solutions

Hohl Maschinenbau serves as a partner from the design to the production of your assemblies.

Express production

Time is of the essence? We offer short delivery times and the shortest possible lead times from design to delivery!

Customized solutions